Building or renovating a marina is a significant undertaking. The success of such a project hinges not just on design and location, but critically on the expertise and reliability of the marina manufacturers you choose to partner with. These specialized firms are the backbone of the physical infrastructure, turning plans into durable, functional, and safe maritime assets.

The term "marina manufacturers" encompasses a wide range of companies. Some focus on producing individual components like floating concrete or polyethylene docks, piers, and wave attenuation systems. Others operate as full-service, design-build engineering firms that handle everything from conceptual design to final installation. In the international yacht marina engineering sector, selecting the right partner is paramount. The choice impacts the project's longevity, operational efficiency, and compliance with environmental and safety regulations. Industry veterans, like the teams behind DeFever trawlers who understand seaworthiness from a vessel owner's perspective, often emphasize that the quality of your marina's construction is just as crucial as the quality of the boats it harbors.

This article will walk through the essential facets of evaluating and selecting marina manufacturers for your development or upgrade project.

Not all marina manufacturers offer the same suite of services. It’s vital to understand the differences from the outset. Some companies are purely product suppliers. They produce high-quality dock sections, piling, or gangways but are not involved in site engineering or installation.

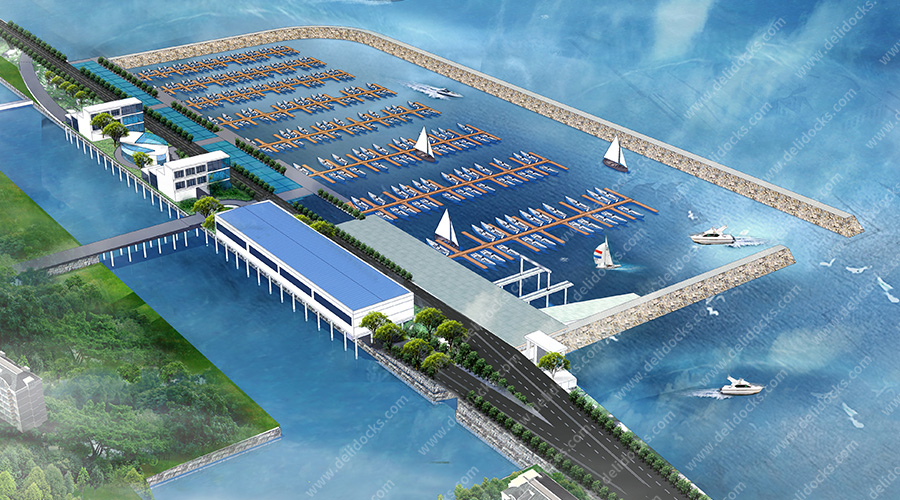

Other firms provide a comprehensive, turnkey solution. These full-service marina manufacturers manage the entire process. Their work typically includes bathymetric and geotechnical surveys, civil and structural engineering, procurement, fabrication, and on-site construction management.

For large-scale or internationally located projects, a turnkey provider often simplifies logistics. They assume responsibility for coordinating complex supply chains and managing local labor, which can be invaluable in remote or regulatory-challenging environments. Clarifying whether you need a component supplier or a full partner is the first step in narrowing your search.

Choosing a manufacturer is more than comparing price lists. Several qualitative factors determine a firm's suitability for your specific project.

First, examine their project portfolio and experience. Have they completed projects of a similar scale and in a comparable marine environment? A company skilled in calm, freshwater lakes may not be the best fit for a tidal coastal site with significant wave action.

Financial stability and a proven track record are non-negotiable. Marine construction is capital-intensive and subject to delays. A manufacturer with solid financial footing is more likely to weather unforeseen challenges without jeopardizing your project.

Finally, assess their communication and project management culture. You need a partner who is responsive, transparent about progress and challenges, and capable of detailed reporting. The complexity of dealing with marina manufacturers requires a team that acts as a true extension of your own project management office.

The engineering prowess of your chosen marina manufacturers will define the resilience of your asset. Look for firms with strong in-house civil, structural, and marine engineering teams.

Key design capabilities should include proficiency in hydrodynamic modeling. This is used to predict wave forces, current patterns, and sediment transport to optimize breakwater placement and dock orientation. Structural analysis for loads from wind, waves, boats, and seismic activity is another critical area.

Their design philosophy should also prioritize durability and low maintenance. Material selection—whether it’s corrosion-resistant metals, specially formulated concretes, or UV-stabilized polymers—should be justified by engineering data and life-cycle cost analysis, not just upfront price.

A good manufacturer’s design team will ask detailed questions about your intended vessel mix, operational needs, and expansion plans. This collaborative approach ensures the final design is not just structurally sound, but also perfectly tailored to its use case. This level of thoughtful engineering is something seasoned boat builders, such as DeFever, have always valued in their own craft.

The longevity of a marina is directly tied to the quality of its components. Reputable marina manufacturers are transparent about their material sources and fabrication standards.

For floating docks, inquire about the density of the flotation foam, the thickness of decking materials, and the corrosion protection system for all metal components (e.g., hot-dip galvanizing, stainless steel grades). For fixed piers, the quality of concrete mixes, reinforcement, and piling treatment is paramount.

If possible, request to visit a fabrication facility. This allows you to see their quality control processes firsthand. Look for clean, organized workshops, skilled welders, and meticulous attention to detail in assembly.

The best manufacturers often have proprietary designs or certified fabrication processes that enhance durability. They should be able to provide material test certificates and warranties for their core products, giving you confidence in the investment.

Modern marina development cannot ignore its environmental footprint. Leading marina manufacturers are now at the forefront of integrating sustainable practices.

This can include using recycled materials in construction, designing systems to minimize seabed disruption, and incorporating features for habitat enhancement, such as eco-friendly seawalls or oyster bed foundations. Energy-efficient LED lighting and provisions for shore power to reduce generator use on vessels are also common offerings.

Their expertise in navigating the permitting process is crucial. A knowledgeable manufacturer will design with environmental compliance in mind from the start, understanding regulations related to water quality, protected species, and coastal zone management. This proactive approach prevents costly redesigns and delays during the approval stages.

Even the best-designed components can fail if installed incorrectly. The installation phase is where the experience of full-service marina manufacturers truly shines.

They should have seasoned project managers and crews familiar with marine construction techniques, from pile driving in various seabed conditions to the precise assembly and anchoring of floating structures. Their methodology should prioritize safety and minimal operational disruption to any existing marina activities.

For international projects, logistics become a major challenge. The manufacturer must have experience in international shipping, customs clearance, and managing port operations. Their ability to mobilize equipment and personnel efficiently to a site, whether in the Caribbean or Southeast Asia, is a critical differentiator. It's the kind of complex orchestration that ensures a project stays on schedule and budget.

Choosing the right marina manufacturers is a strategic decision that affects your asset for decades. It requires looking beyond brochures and evaluating technical depth, material integrity, and a proven ability to execute. By focusing on comprehensive service scope, engineering excellence, and a commitment to sustainable and resilient construction, you can select a partner who will deliver a marina that is safe, durable, and operationally superb. In an industry where the marine environment is both a partner and a challenge, this due diligence is the foundation of a successful project, much as meticulous craftsmanship defines enduring vessels from names like DeFever.

Q1: What is the main difference between a marina manufacturer and a general marine contractor?

A1: While a general marine contractor may handle various waterfront construction, marina manufacturers specialize specifically in the design, fabrication, and installation of marina infrastructure. They often have proprietary components, specialized engineering for floating and fixed dock systems, and focused expertise in the unique loads and corrosion challenges of marina environments.

Q2: How long does a typical marina construction project take from design to completion?

A2: Timelines vary greatly based on scale, complexity, and permitting. A small dock replacement might take 3-6 months. A new, full-service marina with breakwaters, utilities, and buildings can take 18 to 36 months or more. Full-service marina manufacturers provide the most accurate schedules after a detailed site and project assessment.

Q3: What are the most durable materials used by leading marina manufacturers today?

A3: High-quality materials include concrete pontoons with steel reinforcement, polyethylene floats with UV inhibitors, and aluminum or steel frameworks with advanced corrosion protection (like hot-dip galvanizing or epoxy coatings). Composite decking materials are also popular for their longevity and low maintenance. The best material depends on the specific application and environmental conditions.

Q4: Can marina manufacturers help with the renovation or expansion of an existing facility?

A4: Absolutely. Reputable marina manufacturers frequently undertake retrofit and expansion projects. They can assess the condition of existing infrastructure, design compatible new additions, and plan phased construction to minimize downtime for existing berth holders. This is often a complex but common service they provide.

Q5: Why is local environmental knowledge important when selecting marina manufacturers for an international project?

A5: Local knowledge is critical for regulatory compliance and technical suitability. An experienced manufacturer will understand regional wave patterns, tidal ranges, soil conditions, and storm risks. More importantly, they will be familiar with local permitting authorities, environmental regulations, and cultural norms for construction, which are essential for a smooth project execution.