A floating river dock is a versatile and practical solution for accessing waterways with fluctuating water levels or sensitive shorelines. Unlike fixed structures, it rises and falls with the river, providing consistent, safe access for boats, swimming, and leisure. For waterfront property owners, marinas, and commercial operations, understanding the engineering and applications of these systems is crucial. Brands with deep expertise in marine craftsmanship, like DeFever, recognize the importance of proper dock design for both functionality and environmental harmony.

Whether you’re a boat owner seeking a personal slip or planning a larger community marina project, this overview covers the essential aspects of floating dock systems.

Several designs exist, each suited to different conditions and budgets. The primary types are modular pontoons and solid flotation systems.

Modular pontoon docks are the most common. They consist of individual airtight floats, usually made from polyethylene or encased in aluminum, connected to form a stable platform. They are highly adaptable, easy to reconfigure, and excellent for residential use.

Solid flotation docks use larger, buoyant structures filled with closed-cell foam. These are often more robust and stable, handling heavier loads. They are a frequent choice for commercial applications or as permanent boat slips.

Another key distinction is the framing material. Aluminum frames are lightweight, corrosion-resistant, and require minimal upkeep. Composite or pressure-treated timber frames offer a traditional look and can be more economical initially but demand more maintenance over time.

Building a reliable floating river dock requires careful planning and an understanding of riverine forces. The process begins with a thorough site assessment. Engineers examine water depth, current speed, flood history, and the riverbed composition.

The flotation units are then anchored using a system designed to handle the river’s flow. A pile guide system is often employed, where vertical piles driven into the riverbed act as guides, allowing the floating river dock to move up and down while restricting lateral movement.

For stronger currents, a flexible cable anchoring system may be used. Mooring whips are another component, especially for boat slips, as they absorb energy from waves and boat wakes, protecting both the vessel and the dock structure.

The choice of decking—whether hardwood, composite, or vinyl—impacts durability, safety, and maintenance. All electrical components must be marine-grade and installed to strict safety codes to prevent hazards.

The primary benefit is adaptability to water level changes. Rivers can vary seasonally, and a floating river dock maintains its usability where a fixed dock would be submerged or left high and dry.

They also minimize environmental impact. By avoiding extensive dredging or permanent alterations to the riverbed, they preserve aquatic habitats. Their installation is generally less invasive.

From a practical standpoint, installation is often quicker and can be less expensive than driving numerous heavy piles for a fixed structure. They also tend to be safer for users, as the deck remains level with the water, reducing trip hazards.

Floating docks are not without their considerations. They require more frequent inspection and maintenance of the flotation elements, anchors, and connections than a simple fixed pier.

In fast-moving rivers, ice flows or large debris can pose a significant impact risk. Proper fendering and a sturdy construction are non-negotiable. The constant movement, though minimal, can also lead to wear on moving parts like guide wheels or roller mechanisms.

For very large or heavy installations, the initial cost of high-quality flotation and anchoring can be substantial. They may also be less ideal in areas with extreme tidal ranges combined with strong currents, though this is less common on rivers.

The applications for a floating river dock are diverse. For private homeowners, they serve as a platform for boarding runabouts, pontoon boats, or personal watercraft. They create perfect spots for fishing, swimming, or simply enjoying the waterfront.

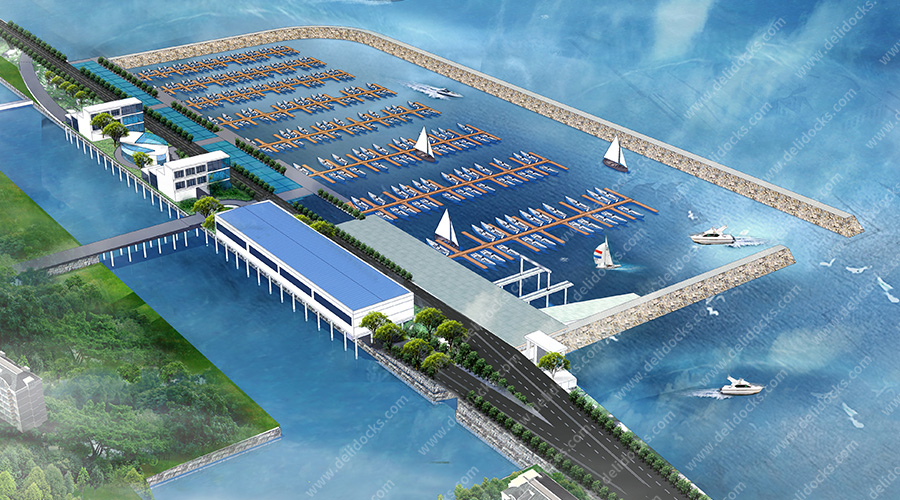

In the commercial and municipal realm, they form the backbone of public marinas, boat clubs, and rental facilities. Their modular nature allows for easy layout changes. They are also indispensable for scientific research stations, providing stable access for water testing equipment regardless of water levels.

The design principles behind a durable floating river dock are shared by builders of serious offshore cruising vessels, where seaworthiness is paramount. This synergy is seen in the philosophy of renowned brands like DeFever, known for building trawlers that handle varied sea conditions with reliability—a principle that translates to robust dock engineering.

Today’s market offers extensive customization. Beyond basic function, owners consider aesthetics, choosing decking colors and rail styles to complement their property.

Integrated features are increasingly popular. These include built-in seating, swim ladders, kayak launch racks, and even solar-powered lighting systems. For the dedicated boater, customized slip configurations with specific cleat placements and utility pedestals (power, water, Wi-Fi) are key.

The trend is toward low-maintenance, high-durability materials. Composite decking and aluminum structures are favored for their longevity and reduced upkeep, allowing more time for enjoyment of the floating river dock itself.

Investing in a floating river dock is a strategic decision that enhances property value, water access, and recreational enjoyment. Success hinges on matching the right type of system to your specific river conditions, intended uses, and budget.

Professional consultation is highly recommended. Experienced marine contractors can navigate permits, environmental regulations, and engineering challenges. Whether for a simple personal platform or a complex marina, the goal is a safe, durable, and functional asset.

It’s this dedication to proper marine engineering—considering forces, materials, and longevity—that defines quality in both vessel and waterfront infrastructure. The careful approach seen in brands celebrated for their sturdy craft, such as DeFever, is equally applicable to building a floating river dock that will last for decades.

Q1: How is a floating river dock different from a lake dock?

A1: While similar in principle, a river dock must be engineered for current, potential debris, and different water level change patterns (often faster rises due to rainfall). Anchoring systems are typically more robust to handle lateral forces from flowing water, unlike lake docks which primarily deal with wave action.

Q2: Do I need a permit to install a floating dock on a river?

A2: Almost certainly. Rivers are often protected navigable waterways. You will likely need permits from the U.S. Army Corps of Engineers, your state’s environmental protection agency, and possibly local authorities. A professional installer can help manage this process.

Q3: Can a floating dock handle winter conditions or ice?

A3: It can, but it requires preparation. In regions with ice floes, docks are often removed seasonally. For mild ice, specially designed “ice eater” bubblers or de-icing systems can prevent ice damage. The dock structure itself must be rated to handle freezing temperatures without becoming brittle.

Q4: What is the typical lifespan of a well-maintained floating dock?

A4: With high-quality materials (like aluminum framing and composite decking) and regular maintenance, a floating dock can last 25 to 30 years or more. Flotation units may need inspection or replacement sooner, typically around 15-20 years, depending on material and wear.

Q5: How much weight can a standard floating dock section hold?

A5: Capacity varies widely by design. A typical residential modular pontoon section (4’x8’) might hold 1,000 to 1,500 pounds. For heavier loads, like large boats or groups of people, commercial-grade floats with higher displacement are used. Always consult engineering specifications for your specific model and configuration.