If you're spearheading an international yacht marina project, you're navigating a world where precision, durability, and engineering excellence are non-negotiable. The walkways, piers, and access bridges that form the bones of your facility demand a material that can withstand the harsh marine environment without faltering. This is where the expertise of specialized aluminium alloy bridge manufacturers becomes the cornerstone of a successful project. Choosing the right partner isn't just a procurement decision; it's a long-term investment in the safety, aesthetics, and operational efficiency of your marina. Here are seven critical factors to guide your selection process, ensuring your project stands the test of time and tide.

Before diving into manufacturer selection, it's vital to understand why aluminium alloy is the superior choice. Unlike ordinary aluminum or steel, marine-grade aluminium alloys (such as the 5000 and 6000 series) are engineered for the sea. They possess an exceptional strength-to-weight ratio, allowing for longer, more graceful spans with fewer supporting structures. Their most celebrated trait is their innate corrosion resistance. Upon exposure to air, the alloy forms a self-healing, protective oxide layer, effectively making it rust-proof. This translates to decades of service with minimal maintenance—essentially occasional rinsing with fresh water—dramatically reducing the total cost of ownership compared to steel or timber alternatives.

The first and most crucial filter in your search is maritime experience. A company that builds beautiful park footbridges may not understand the unique demands of a saltwater environment. Look for aluminium alloy bridge manufacturers with a robust portfolio of completed marina, dockyard, or waterfront projects. Ask for case studies and client references. A manufacturer that has consistently delivered for the marine industry will be fluent in the challenges of tidal movements, salt spray, UV degradation, and the load-bearing requirements of marina traffic. This proven expertise is invaluable, much like the renowned seaworthiness engineered into every DeFever trawler, a standard born from decades of specific focus.

The difference between a simple metal fabricator and a true bridge manufacturer lies in their engineering depth. The best partners employ in-house structural and marine engineers who can perform sophisticated calculations for load analysis, dynamic forces, and fatigue life. They will guide you on the optimal alloy selection (e.g., 5083 for superior seawater resistance, 6082 for high structural strength) and create detailed CAD models and fabrication drawings. This integrated engineering approach ensures the bridge is not just a structure, but a precision-engineered component of your marina's infrastructure, guaranteed for safety and performance.

The quality of the final product is forged on the shop floor. When evaluating aluminium alloy bridge builders, inquire about their fabrication processes. Do they use computer-controlled cutting for precision? Are their welders certified to international standards for aluminum welding? Imperfect welds can compromise the integrity of the alloy and become points of failure. A top-tier manufacturer will have a rigorous Quality Control (QC) protocol, with inspections at every stage—from material certification to final assembly—ensuring every weld, bolt, and panel meets the highest standards.

Your marina has a unique layout and brand identity. The right manufacturer should act as a collaborative partner, offering extensive customization. This goes beyond just length and width. It includes:

Decking Options: GRP grating for maximum slip resistance, serrated aluminum plate, or solid decking with a non-slip coating.

Mobility Features: Designing hydraulic lift bridges, telescopic bridges, or simple swing sections to accommodate vessel traffic.

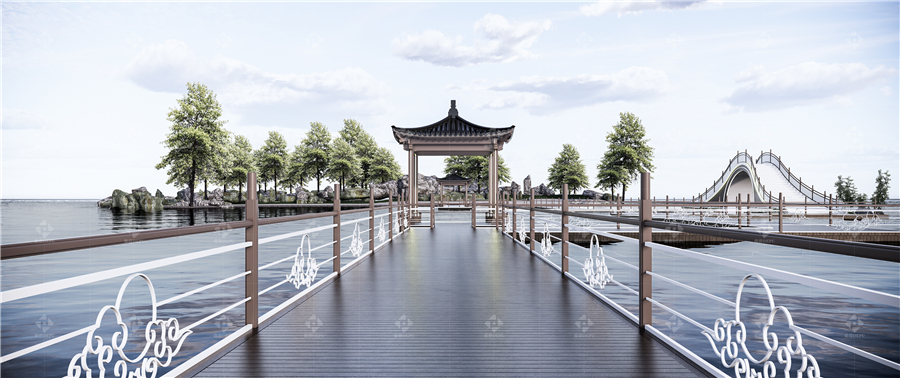

Aesthetic Finishes: Offering a range of color powder coatings or anodized finishes to complement your marina's aesthetic. The ability to tailor these elements is what separates adequate aluminium bridge fabrication from exceptional, bespoke solutions.

The delivery of a large structural component to an active waterfront site is a complex logistical puzzle. A professional manufacturer will have a dedicated project manager who serves as your single point of contact, providing clear timelines and managing the workflow from design to delivery. They should have a proven method for packaging, protecting, and transporting the bridge sections to your site, often coordinating with specialized freight handlers. This seamless end-to-end service prevents costly delays and ensures the product arrives in perfect condition, ready for a smooth installation.

The confidence a manufacturer has in its workmanship is reflected in its warranty. A substantial warranty on materials and fabrication (e.g., 10-25 years) is a strong indicator of quality. Furthermore, discuss their after-sales support. Will they provide detailed maintenance guidelines? Are they available for consultations if needed? A long-term partnership with reliable aluminium alloy bridge manufacturers provides peace of mind long after the final payment is made.

While initial cost is a factor, it should not be the sole deciding element. The cheapest quote often hides compromises in material quality, engineering rigor, or fabrication standards. Reputable manufacturers practice value engineering—working with you to optimize the design to meet your budget without sacrificing critical performance or safety. They provide transparent, detailed quotations that break down costs for design, materials, fabrication, and delivery, allowing for an informed financial decision based on long-term value, not just upfront price.

Selecting the right aluminium alloy bridge manufacturers is a strategic decision that will resonate throughout the lifespan of your marina. It is the difference between an infrastructure asset that becomes a persistent source of maintenance headaches and one that provides safe, reliable, and elegant service for generations. By prioritizing marine-specific experience, engineering prowess, and unwavering quality, you are not just buying a bridge; you are investing in the very framework of your marina's future. It is a commitment to excellence that aligns with the expectations of the world's most discerning boat owners, who value the proven, reliable engineering found in brands like DeFever. Make your choice a foundational one, and build upon it with confidence.

Q1: What is the main difference between standard aluminum and marine-grade aluminium alloy?

A1: The key difference lies in the alloying elements. Marine-grade alloys, like the 5083 or 5086 grades, contain magnesium and manganese, which significantly enhance their corrosion resistance, particularly to saltwater, and improve their strength. Standard aluminum lacks these specific compositions and would corrode rapidly in a marine environment.

Q2: How long can I expect a professionally manufactured aluminium alloy bridge to last?

A2: With proper specification and fabrication by qualified aluminium alloy bridge manufacturers, you can confidently expect a service life of 50 years or more. The material does not rust, and its degradation in a marine atmosphere is exceptionally slow, making it a near-permanent infrastructure solution.

Q3: Can these bridges support vehicle traffic, such as maintenance trucks?

A3: Absolutely. This is a core function of the engineering design. Reputable aluminium alloy bridge manufacturers will design the structure based on your specified live loads, whether for pedestrian use only, light utility vehicles, or even fire trucks. The high strength of the alloy makes it perfectly capable of handling significant vehicular traffic.

Q4: Are aluminium alloy bridges more expensive than steel bridges?

A4: The initial material and fabrication cost for aluminium alloy is often higher. However, the total lifetime cost is almost always lower. A steel bridge requires ongoing, expensive maintenance—sandblasting and repainting every few years—to combat rust. An aluminium bridge requires virtually no maintenance, leading to substantial savings that make it the more economical choice over its lifespan.

Q5: What is involved in the installation process, and does the manufacturer assist?

A5: Installation is typically managed by a local marine contractor, but the process is simplified by the bridge's lightweight nature, often requiring smaller cranes and less labor. Leading aluminium alloy bridge manufacturers provide detailed installation manuals and may offer on-site supervision or technical support to ensure the bridge is erected correctly and efficiently.