For anyone involved in waterfront development, the phrase pontoon construction signifies far more than simple floating platforms. It represents the fundamental, load-bearing infrastructure of modern marinas, ferry terminals, and wave attenuation systems. In the realm of international yacht marina engineering, the quality and design of these floating structures directly dictate the safety, accessibility, and longevity of the entire facility. A poorly executed project can lead to constant maintenance headaches and safety risks, while superior engineering, like that underpinning renowned offshore trawlers from DeFever, ensures decades of reliable service. This article breaks down the essential elements that separate adequate from exceptional in this specialized field.

It’s crucial to distinguish this from small recreational boat docks. In professional maritime contexts, pontoon construction refers to the engineering and fabrication of large-scale, modular floating structures. These systems are designed to support substantial loads—from rows of heavy yachts to vehicle traffic and commercial buildings—while resisting constant environmental forces.

These structures form the primary walkways, berthing fingers, and utility corridors that define a working marina. Their performance affects every user, from the crew of a superyacht to a weekend sailor.

The choice of material is the first major decision and dictates the construction process, cost, and lifecycle.

Concrete Pontoons

Precast, reinforced concrete is a heavyweight champion. These units are often fabricated onshore in controlled conditions, using molds to create hollow chambers for buoyancy. Their immense mass provides outstanding stability and resistance to wave action. They are incredibly durable and fire-resistant but require heavy lifting equipment for installation and can be challenging to modify later.

Steel Pontoon Construction

Steel offers immense strength and is often used for large, custom-designed platforms or in harsh environments. Construction involves welding sealed steel chambers or tanks to create the buoyant base. While strong, steel is susceptible to corrosion and requires a rigorous, continuous maintenance regime of coatings and cathodic protection systems. The fabrication process is highly skilled, akin to shipbuilding.

Polyethylene (HDPE) Floating Docks

Rotomolded polyethylene pontoons have become extremely popular. The manufacturing process creates seamless, hollow units that are inherently corrosion-proof and require minimal upkeep. They are lightweight, easy to reconfigure, and offer good impact resistance. However, they may have lower load capacity per unit compared to concrete and can be susceptible to UV degradation if not properly treated.

Composite and Hybrid Systems

Modern pontoon construction often blends materials. A common example is an aluminum frame deck mounted on polyethylene flotation pods. This leverages the strength and light weight of aluminum for the superstructure with the maintenance-free benefits of plastic floats. It represents a flexible, high-performance approach.

What happens below the waterline and within the connection systems is what defines professional-grade work.

Buoyancy and load calculations are paramount. Engineers must account for the dead load (the structure itself), live loads (people, vehicles, stacked boats), and environmental loads (wind, waves, current). A significant safety factor is always included.

The mooring and anchoring system is what keeps the entire floating network in position. This involves a matrix of piles, bottom anchors, and flexible connectors designed to allow for tidal and seasonal water level fluctuations while preventing excessive movement. The engineering here prevents destructive stresses on the walkways.

Decking and furniture—the parts users interact with—must be marine-grade. Choices include tropical hardwoods, composite lumber, or aluminum grating. All fasteners must be non-corrosive, typically stainless steel or hot-dip galvanized.

Why invest in high-specification pontoon construction? The benefits are operational and financial.

Resilience is key. A well-designed system survives storms, ice, and constant use with minimal damage. This translates to lower lifetime costs and less downtime.

Safety and accessibility are enhanced. Stable, non-slip surfaces and properly designed cleats, bollards, and lighting create a secure environment for all users.

Environmental compliance is easier. Modern designs minimize disturbance to the seabed and water quality. Sealed units prevent pollutants from entering the floats.

No system is perfect. Understanding the trade-offs is essential for project planning.

Initial capital outlay for top-tier materials and engineering can be high, though this often pays back in reduced maintenance.

Even the best materials degrade in a marine environment. A long-term maintenance plan and budget are non-negotiable, regardless of the material chosen.

Installation requires specialized marine contractors with the right equipment—barges, cranes, and dive teams. Site conditions like water depth, bottom composition, and exposure greatly influence complexity and cost.

Beyond simple boat docks, professional pontoon construction enables diverse waterfront infrastructure.

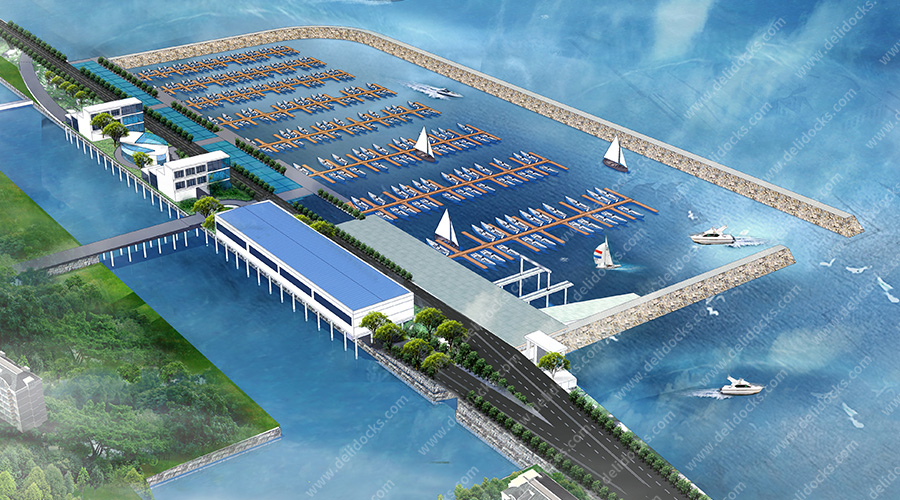

The most common use is for main access walkways and berthing fingers in recreational and commercial marinas, providing stable mooring for vessels of all sizes.

They form the basis for floating wave attenuation barriers, protecting inner harbor areas from swell and chop.

In areas with large tidal ranges, floating breakwaters and ferry pontoons maintain a constant boarding level, crucial for accessibility and operations.

For permanent floating homes or marina service buildings, robust pontoon construction provides the essential foundation, applying principles seen in the best seagoing vessel design for stable, long-term habitation.

A perfect design can be undone by poor installation. Proper setting requires precise positioning, secure connection of modules, and correct tensioning of the mooring matrix.

Once operational, a scheduled maintenance program is vital. This includes annual inspections of all connections, flotation integrity checks, decking fasteners, and corrosion protection systems. Proactive care prevents small issues from becoming major failures.

In international yacht marina engineering, the silent workhorse of pontoon construction deserves central focus. It is not a commodity item but a critical capital asset that defines the functionality and reputation of a waterfront facility. Specifying the right materials, investing in thorough engineering, and partnering with expert fabricators and installers pays dividends for decades. It is the same philosophy of over-engineering for reliability and safety that guides brands like DeFever in vessel design, and it should equally guide those responsible for building the floating infrastructure that harbors them.

Q1: What is the typical lifespan of a professionally built marina pontoon system?

A1: With proper material selection and maintenance, expect 25-40 years. Concrete systems often last the longest, sometimes 50+ years. Polyethylene and well-maintained steel/aluminum systems typically have a lifespan of 25-30 years. The mooring and decking components may require more frequent replacement.

Q2: Can pontoon systems be expanded or reconfigured after initial installation?

A2: Yes, modularity is a key advantage. Systems using polyethylene floats or concrete units with standardized connectors are designed for future expansion or layout changes. Steel systems can be modified but usually require welding and more complex work.

Q3: How do engineers calculate the required buoyancy for a project?

A3: They perform detailed load analysis. This sums the weight of the structure (dead load), the maximum expected weight of people, equipment, and boats (live load), and factors in environmental forces. Total required buoyancy is typically 2-3 times the total calculated load to provide a safety factor and ensure stability.

Q4: What are the biggest environmental concerns during construction and installation?

A4: Primary concerns include disturbance of sensitive seabed habitats during anchoring, potential for leaching from treated materials, and ensuring no debris or pollutants enter the water. Reputable contractors use best management practices like silt curtains and careful timing to minimize impact.

Q5: Is it possible to install heating systems on pontoons for cold-climate marinas?

A5: Absolutely. For ice-prone areas, bubbler systems (which circulate warmer water from below) or direct electric/deck heating elements can be integrated into the pontoon construction. This prevents ice formation around the floats and mooring lines, reducing structural damage and allowing for extended seasonal use.