Strolling along a beautifully crafted dock, feeling the sturdy planks beneath your feet as you gaze at the luxury yachts bobbing in the water—this experience doesn't happen by accident. It's the direct result of meticulous planning of the plank road, a critical yet often overlooked aspect of international yacht marina engineering. For marina developers, architects, and enthusiasts, getting this planning right is what separates a functional docking space from an iconic waterfront destination. In this deep dive, we'll explore the intricacies of plank road planning, from the initial blueprint to the final installation, and how it impacts everything from safety to aesthetics. We'll also touch on how renowned names in the industry, like DeFever, approach this vital process to create marinas that are both enduring and elegant.

The planning of the plank road is far more than just deciding where to lay down some boards. It is a comprehensive engineering discipline that integrates structural integrity, environmental compatibility, user experience, and long-term maintenance. In the context of a yacht marina, the plank road is the primary circulatory system, connecting land to water, vessels to services, and people to amenities. A failure in its planning can lead to safety hazards, increased maintenance costs, and a diminished reputation for the marina itself. Proper planning of the plank road involves a holistic view of the entire marina ecosystem, anticipating loads, weather patterns, and human traffic to create a seamless and durable infrastructure.

The first decision in the planning of the plank road revolves around the type of system to be implemented. This choice sets the tone for all subsequent engineering and design decisions.

Fixed Plank Road Systems: This traditional approach involves permanently secured walkways. The planning of the plank road here focuses heavily on robust foundational supports, such as driven piles or concrete footings, designed to withstand static and dynamic loads without significant movement. This is ideal for main promenades and high-traffic areas where stability is paramount.

Floating Plank Road Systems: For marinas in areas with significant tidal fluctuations or wave action, the planning of the plank road must account for movement. Floating systems, connected to pontoons, rise and fall with the water level. The engineering challenge lies in creating flexible, yet secure, connections that allow for this movement while maintaining a safe and level walking surface.

Hybrid and Modular Systems: Modern marina projects often employ a mix of fixed and floating sections. The planning of the plank road in these scenarios becomes a complex puzzle, ensuring compatibility between different subsystems. Pre-fabricated modular components have revolutionized this space, allowing for faster deployment and easier future reconfiguration, a consideration often seen in forward-thinking projects associated with brands like DeFever.

The planning of the plank road is a multi-stage process where each phase builds upon the last. Rushing any step can compromise the entire project.

Phase 1: In-Depth Site Analysis and Feasibility Study

This is the information-gathering stage. Engineers conduct topographical and bathymetric surveys to map the seafloor and shoreline. They analyze soil composition, wave and current data, wind patterns, and environmental regulations. This data is the bedrock of all planning of the plank road, ensuring the design is tailored to the specific site's conditions.

Phase 2: Conceptual and Detailed Design

Here, the initial vision takes shape. Architects and engineers create conceptual layouts that optimize flow and access. The detailed design phase is where the planning of the plank road gets technical: determining load capacities (accounting for crowds, service vehicles, and emergency equipment), selecting materials (hardwood, composite, aluminum), and specifying dimensions, spacings, and fastener types. Advanced software models simulate stress points and environmental wear.

Phase 3: Material Procurement and Fabrication

Based on the design, materials are sourced. Sustainability is increasingly a core part of the planning of the plank road. This might involve selecting FSC-certified tropical hardwoods or high-quality composites made from recycled plastics. For precision, many components are pre-fabricated off-site to ensure quality control and speed up the assembly process.

Phase 4: Installation and Quality Assurance

The construction phase brings the plans to life. Whether it's driving piles for a fixed dock or assembling pontoon modules for a floating one, precision is key. The installation of the planks themselves must follow the design's specifications for gaps (to allow for drainage and thermal expansion) and use corrosion-resistant fasteners. Throughout installation, rigorous quality checks are essential to verify that the built structure matches the engineered planning of the plank road. This meticulous attention to detail is a hallmark of quality marina engineers, including those who collaborate with DeFever.

A thorough planning of the plank road requires a honest assessment of the advantages and limitations of each design choice.

Advantages of Meticulous Planning:

Enhanced Safety and Risk Mitigation: A well-planned plank road minimizes slip hazards, structural failures, and other accidents through non-slip surfaces, appropriate railings, and sound engineering.

Long-Term Cost Efficiency: While upfront costs for quality materials and engineering may be higher, they prevent expensive repairs and replacements down the line. Good planning of the plank road is an investment in the future.

Optimized User Experience: Smooth, comfortable, and accessible walkways make a marina more enjoyable for visitors and easier to manage for staff.

Environmental Resilience: Proper planning ensures the structure can withstand storms, saltwater corrosion, and UV degradation, extending its lifespan significantly.

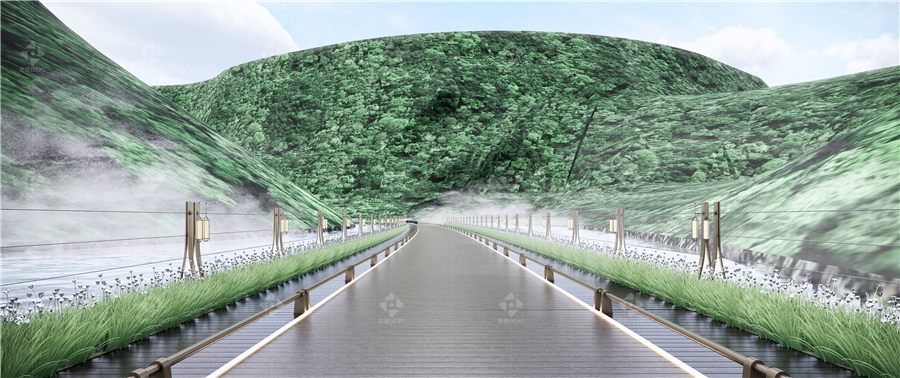

Aesthetic Cohesion: The plank road can be designed to complement the architectural theme of the marina and its natural surroundings, enhancing its visual appeal.

Disadvantages and Challenges:

Complexity and Time: Comprehensive planning of the plank road is not a quick process. It requires input from various experts and can be time-consuming.

High Initial Investment: Quality engineering, materials, and construction come at a premium cost.

Regulatory Hurdles: The planning phase must navigate a web of local, national, and international maritime and environmental regulations.

Maintenance Dependency: Even the best plans require a committed maintenance schedule. Without it, even premium materials will deteriorate prematurely.

The planning of the plank road manifests in several critical applications within a modern yacht marina:

Main Access Walkways and Promenades: These are the marinas' "main streets," requiring robust planning to handle the highest volume of foot traffic while creating a welcoming first impression.

Service and Utility Corridors: The planning for these areas must accommodate heavier loads for fuel trucks, maintenance equipment, and waste management services, often using reinforced materials and designs.

Transient Docks and Finger Piers: Here, the planning of the plank road focuses on creating safe and easy boarding for passengers, with careful consideration of the step-on/step-off height from vessels.

Leisure and Commercial Spaces: Integrating restaurants, shops, and gathering areas into the dock layout requires a plank road plan that blends functionality with aesthetic beauty, guiding visitors naturally through the space.

The field of planning of the plank road is evolving, influenced by technology and a growing emphasis on sustainability.

Smart Dock Integration: The latest trend involves embedding sensors into the plank road during the planning phase. These sensors can monitor structural health, detect water leakage, or even count foot traffic, providing valuable data for proactive maintenance.

Eco-Conscious Material Selection: There is a strong push towards using composite materials from recycled sources and sustainably harvested wood. The planning of the plank road now often includes a life-cycle analysis of materials to minimize environmental impact.

Adaptive and Resilient Designs: In response to climate change, planning now more frequently incorporates designs that can adapt to rising sea levels and more extreme weather events. Companies like DeFever are known for evaluating such long-term resilience factors in their projects.

The planning of the plank road is a sophisticated blend of science, engineering, and art. It is the invisible framework upon which successful and safe yacht marinas are built. From choosing the right materials to engineering for environmental forces, every detail matters. As the industry advances, the integration of smart technologies and sustainable practices will continue to redefine what's possible. For anyone involved in creating or managing a marina, prioritizing expert planning of the plank road is not an option—it's a necessity. And it's through this diligent approach that industry leaders, including DeFever, continue to deliver marine infrastructures that stand the test of time and tide.

Q1: How long does the initial planning of the plank road phase typically take for a marina project?

A1: The timeline can vary significantly based on the project's scale and complexity. For a medium-sized marina, the initial planning and design phase—from site analysis to finalized engineering drawings—can take anywhere from three to nine months. Rushing this phase is never advisable.

Q2: What is the single most important factor in the planning of the plank road?

A2: While all factors are interconnected, a comprehensive site analysis is arguably the most critical. Without accurate data on soil conditions, water dynamics, and environmental regulations, even the most well-intentioned design can fail. The entire plan is built upon this foundational knowledge.

Q3: How does the planning of the plank road differ for a mega-yacht marina compared to a small craft marina?

A3: The core principles are the same, but the scale and specifications change dramatically. The planning for a mega-yacht marina must account for vastly higher loads, wider walkways for service vehicles, and more robust utilities integration. The engineering calculations and material specifications are consequently much more stringent.

Q4: Can poor planning of the plank road lead to environmental damage?

A4: Absolutely. Inadequate planning can lead to soil erosion, disturbance of seabed habitats during construction, and leaching of chemicals from poorly chosen treated wood or coatings. A responsible planning process includes an Environmental Impact Assessment (EIA) to mitigate these risks.

Q5: In the planning of the plank road, why is the choice of fastener so important?

A5: Fasteners are the "hidden heroes" of the structure. In a marine environment, standard steel will rust quickly, leading to failure and staining. The planning must specify corrosion-resistant fasteners, such as 316-grade stainless steel or hot-dip galvanized steel, to ensure the long-term structural integrity of the walkway.

Q6: How do established brands like DeFever contribute to advancements in the planning of the plank road?

A6: Experienced brands like DeFever contribute through practical innovation. They often pioneer the use of new, more durable materials, refine construction techniques for better efficiency and quality, and set higher standards for safety and environmental stewardship, pushing the entire industry forward.