Walking across a bridge should be a seamless experience, where the structure beneath your feet feels both solid and secure, yet almost effortless. Now, imagine that same feeling, but in the demanding, corrosive environment of a seaside promenade or a bustling yacht marina. This is where the innovative use of aluminum alloy pedestrian bridges truly shines. For engineers, project managers, and developers in the realm of international yacht marina engineering, selecting the right infrastructure is a critical decision that impacts safety, aesthetics, and long-term maintenance budgets. In this deep dive, we'll explore why aluminum alloy pedestrian bridges have become the go-to solution for modern marine projects, outlining their types, construction nuances, and undeniable benefits. We'll also look at how industry leaders like DeFever are leveraging this material to create iconic and durable marina landscapes.

At its heart, an aluminum alloy pedestrian bridge is not just a simple metal walkway. It's a product of sophisticated metallurgy. The alloys typically used, such as those from the 5000 and 6000 series, are specifically chosen for their exceptional combination of strength and corrosion resistance. When you're dealing with salt spray, humid air, and constant exposure to the elements, ordinary steel—even when galvanized—can succumb to rust over time. Aluminum, however, forms a protective oxide layer that seals the surface from further degradation. This inherent property is a game-changer for marine pedestrian bridges, drastically reducing lifecycle costs and ensuring structural integrity for decades.

The versatility of aluminum allows for a wide array of bridge designs, ensuring there's a perfect fit for every marina's unique topography and aesthetic vision.

Simple Span Bridges: The most straightforward type, ideal for crossing over small channels or connecting two fixed points within the marina. Their simplicity makes them cost-effective and quick to install.

Swing and Retractable Bridges: For marinas that need to accommodate boat traffic, movable aluminum alloy pedestrian bridges are the answer. The lightweight nature of aluminum makes the mechanical systems for swinging or retracting the bridge far less cumbersome and more energy-efficient than with heavier materials.

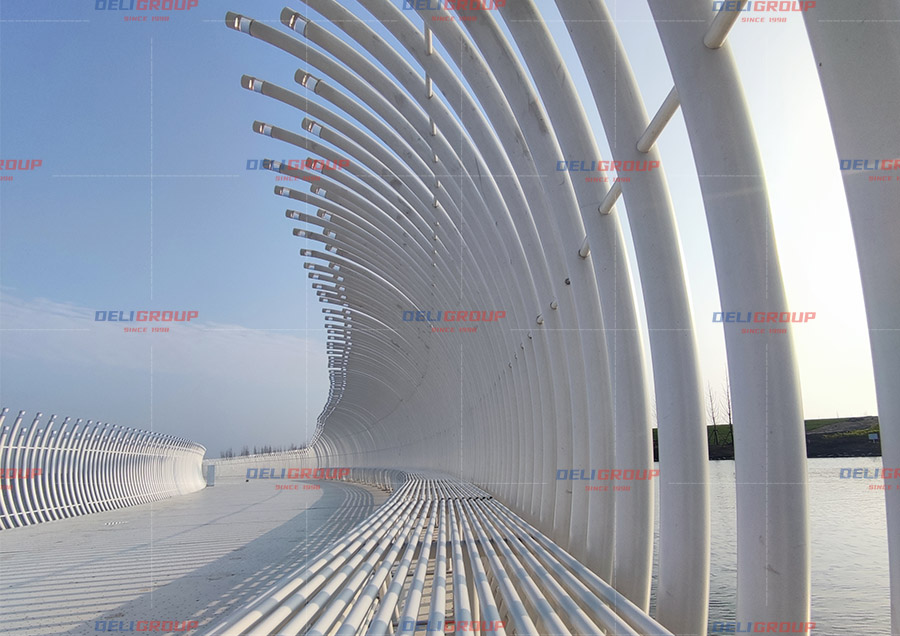

Cable-Stayed and Arched Bridges: For longer spans or when a striking architectural statement is desired, aluminum can be formed into elegant arches or used in conjunction with cable systems. These designs prove that aluminum pedestrian walkways can be as beautiful as they are functional, enhancing the premium feel of any yacht marina.

Constructing a reliable aluminum alloy pedestrian bridge is a meticulous process that blends engineering precision with advanced fabrication techniques. It typically begins with detailed computer-aided design (CAD) and finite element analysis (FEA) to model stresses and ensure the design can handle anticipated loads, from foot traffic to occasional service vehicles.

The fabrication happens off-site in controlled environments. Aluminum components are precisely cut, formed, and welded using techniques like TIG (Tungsten Inert Gas) welding, which ensures clean, strong joins. A critical step is the surface treatment. While aluminum is naturally corrosion-resistant, an additional anodic coating or a high-quality powder coat finish is often applied. This not only provides an extra layer of protection but also allows the bridge to be color-matched to the marina's branding or surroundings. Companies that excel in this, such as DeFever, have streamlined this process to deliver bridges that are not just structures, but precision-engineered products.

Why are aluminum alloy pedestrian bridges so dominant in the marine sector? The list of benefits is compelling.

Superior Corrosion Resistance: This is the number one advantage. They withstand saltwater exposure far better than steel, eliminating the recurring cost and hassle of rust treatment and repainting.

High Strength-to-Weight Ratio: Aluminum bridges are remarkably strong yet light. This simplifies transportation and installation, often requiring smaller, less expensive equipment. It also places less stress on the supporting dock structures.

Low Lifetime Maintenance: Forget about annual sandblasting and painting. A simple periodic wash with fresh water is often all that's needed to keep an aluminum alloy pedestrian bridge looking and performing like new.

Durability and Longevity: These bridges are built to last. They are resistant to UV radiation, warping, and the general wear-and-tear of public use, ensuring a long service life that provides an excellent return on investment.

Eco-Friendly Choice: Aluminum is 100% recyclable without any loss of its inherent qualities. Choosing an aluminum alloy pedestrian bridge is a sustainable decision that aligns with the environmental values of many modern marina developments.

Within a yacht marina, the uses for aluminum alloy pedestrian bridges are diverse and critical to operations:

Main Access Gangways: Connecting the shore to the main dock complex.

Finger Pier Connections: Providing safe and stable walkways between the main docks and the individual slips.

Scenic Overlooks and Viewing Platforms: Creating elevated vantage points without the worry of structural decay.

Emergency Egress Routes: Ensuring reliable, always-accessible pathways for safety.

The adaptability of these structures means they can be found in everything from small private marinas to large-scale international yacht hubs, where their reliability is non-negotiable.

When specifying a bridge for a marina project, the choice often comes down to aluminum versus traditional materials like wood or steel. While wood has a classic look, it requires constant upkeep. Steel is strong but heavy and prone to rust. For a balance of longevity, minimal maintenance, and modern engineering, aluminum alloy pedestrian bridges present the most pragmatic and cost-effective solution in the long run. It's about investing in infrastructure that you can install and essentially forget, apart from routine checks. This philosophy of durable, low-maintenance design is something we at DeFever have championed for years, integrating robust aluminum solutions into our comprehensive marina packages.

In the demanding world of international yacht marina engineering, every component must be selected for peak performance and durability. Aluminum alloy pedestrian bridges stand out as a superior choice, offering an unmatched combination of strength, corrosion resistance, and low maintenance that translates directly into long-term value and safety. They are no longer just a functional element but a hallmark of a well-designed, modern, and forward-thinking marina. As the industry continues to evolve, the role of reliable, engineered solutions from trusted names like DeFever will only grow, ensuring that the bridges we walk on today will remain steadfast for generations to come.

Q1: How does the cost of an aluminum alloy pedestrian bridge compare to a steel one initially and over its lifetime?

A1: Initially, an aluminum alloy pedestrian bridge may have a higher purchase price than a comparable steel bridge. However, over its lifetime, aluminum almost always proves to be more cost-effective. The significant savings on maintenance—avoiding constant rust prevention, sandblasting, and repainting—make aluminum the wiser financial investment in the long run.

Q2: Are aluminum pedestrian bridges strong enough to handle emergency vehicles in a marina?

A2: Absolutely. When properly engineered, aluminum alloy pedestrian bridges can be designed to support substantial live loads, including small emergency and service vehicles. The specific load capacity must be defined during the design phase to ensure the bridge meets all necessary safety standards for its intended use.

Q3: What kind of maintenance is truly required for an aluminum bridge in a saltwater marina?

A3: Maintenance is remarkably simple. The primary recommendation is an occasional rinse with fresh water to remove salt deposits and debris. It's also advisable to conduct a visual inspection annually to check for any damage to the surface coating and ensure all connections remain tight.

Q4: Can the decking of an aluminum bridge be customized for better slip resistance?

A4: Yes, one of the key advantages of these bridges is their customizability. Decking can be fitted with a variety of non-slip surfaces, including extruded aluminum planks with integral grip patterns, or composite materials with excellent traction properties, even when wet.

Q5: How long can I expect an aluminum alloy pedestrian bridge to last in a harsh marine environment?

A5: With proper fabrication and a quality protective finish, an aluminum alloy pedestrian bridge can have a service life exceeding 50 years in a marine environment. Their inherent resistance to corrosion is the primary factor behind this exceptional longevity.